Although handmade jewelry is appreciated for its uniqueness and personal touch, modern technology has revolutionized jewelry production. With the advanced tools and techniques available today, jewelry can be crafted with precision and speed, resulting in almost flawless pieces. From CAD software and 3D printing to laser cutting and CNC machines, technology has made it possible to create intricate designs that were once impossible to achieve by hand. Furthermore, technology has made jewelry production more cost-effective, creating high-quality pieces at more affordable prices. In short, while handmade jewelry will always hold a special place in our hearts, modern technology has elevated the art of jewelry making to new heights.

In the past, jewelry-making began with a handmade prototype, usually silver or gold. Designing and executing the design on the raw material was a time-consuming process. However, artisans still use this method nowadays. On the contrary, many companies, if not the majority, still produce jewelry the old-fashioned way. With technological advancements, jewelry design has become faster and more precise through fast prototyping machines and software. It is now possible to create a ring in 3D within a few hours to a day, which can then be fed to a rapid prototyping machine and produced in either wax, resin, or raw material.

While this technology can produce all types of jewelry, it comes at a cost. While small items like rings, pendants, and earrings can be designed and built using CAD programs, more intricate and larger items can take days to create and may have different finesse than handmade items. The cost of creating complex designs is relatively high due to the need for a master artisan with years of experience and good taste to perfect them. Simple items can be executed quickly using computers due to the extensive library of shapes available for such items. However, such object libraries cannot produce more intricate and complicated jewelry items that require a certain manipulation of the volume and shape.

When to use hand-made jewelry, and when to use technology in jewelry

Jewelry making has transitioned from traditional hand-crafting methods to Computer-Aided Design (CAD) technology. With its precise and accurate abilities, CAD technology has revolutionized the industry by enabling the creation of intricate designs. Cost savings are among the many benefits of CAD technology, as designing jewelry on a computer reduces the time required to create a prototype and minimizes the number of iterations needed.

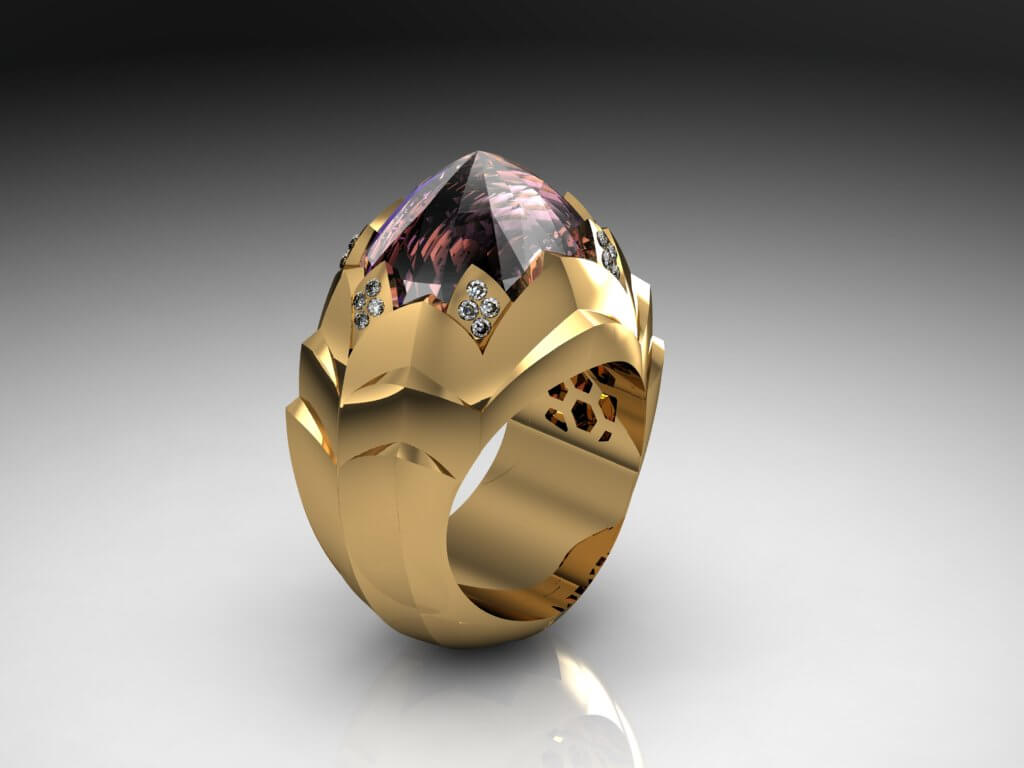

Artisans can now focus their experience on more complex designs with CAD technology. Combining computer-generated and handmade parts can create unique designs that cannot be achieved using traditional methods alone. The finer details of jewelry, such as embellishments and finishes, can be perfected through computer-generated designs, resulting in a superior quality product that meets the customer's expectations. The use of CAD technology has allowed for the creation of one-of-a-kind pieces.

Despite the ongoing use of traditional prototyping techniques, the use of CAD technology when appropriate has become a hallmark in the jewelry industry. Technological advancements may change how jewelry is made in the future. Still, for now, CAD technology remains the best way to save on costs, achieve precise execution of items, and create unique designs that capture the imagination of artisans and customers alike.

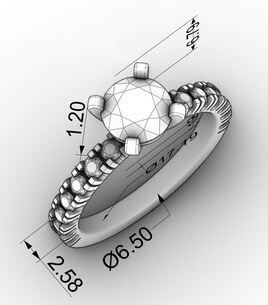

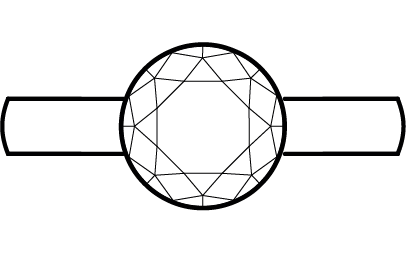

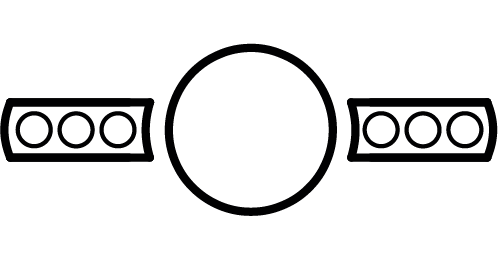

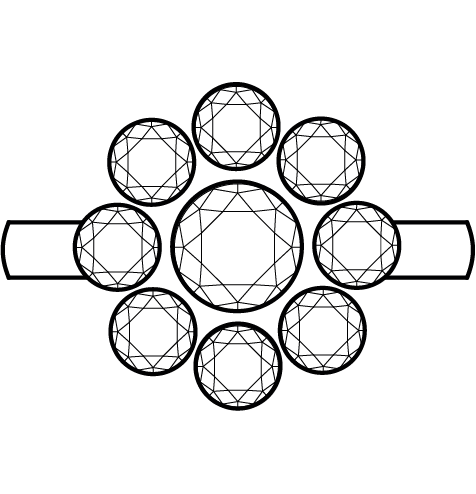

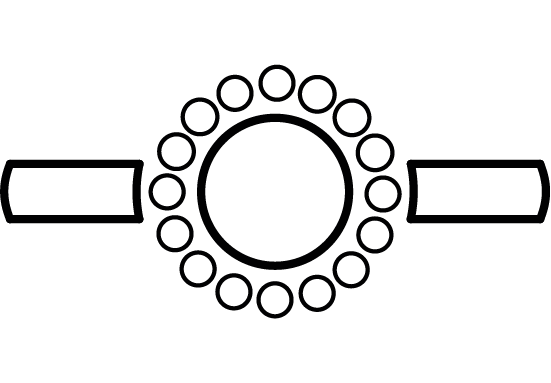

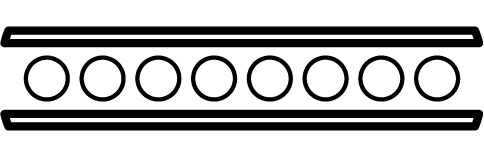

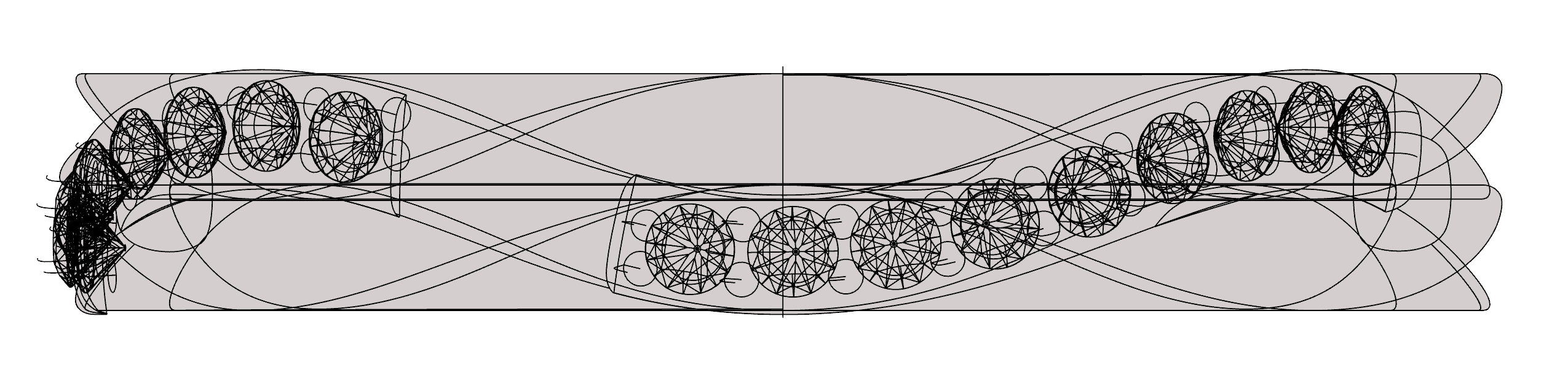

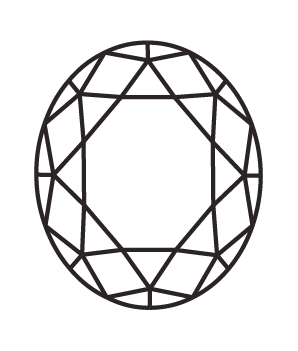

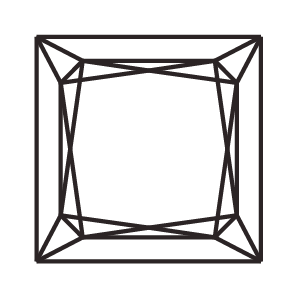

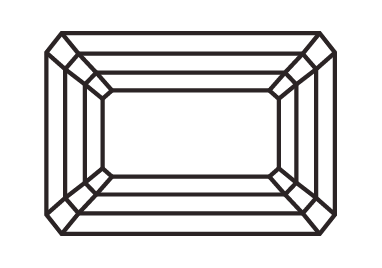

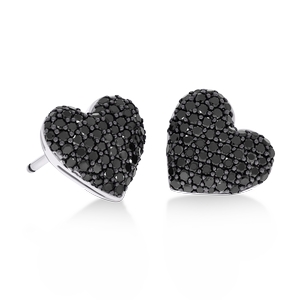

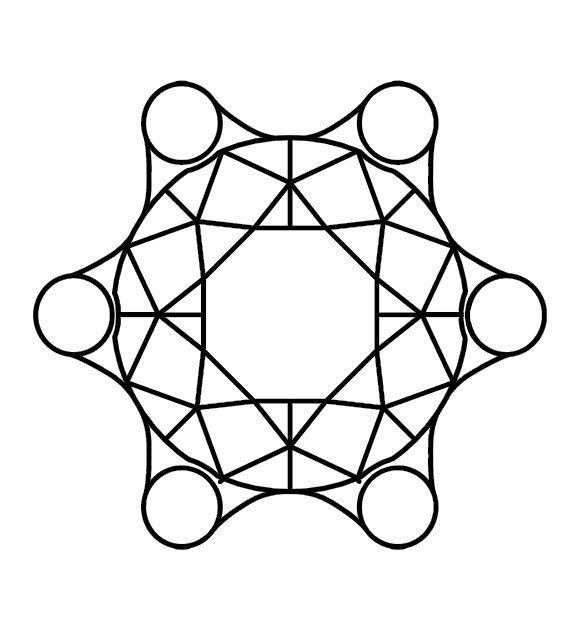

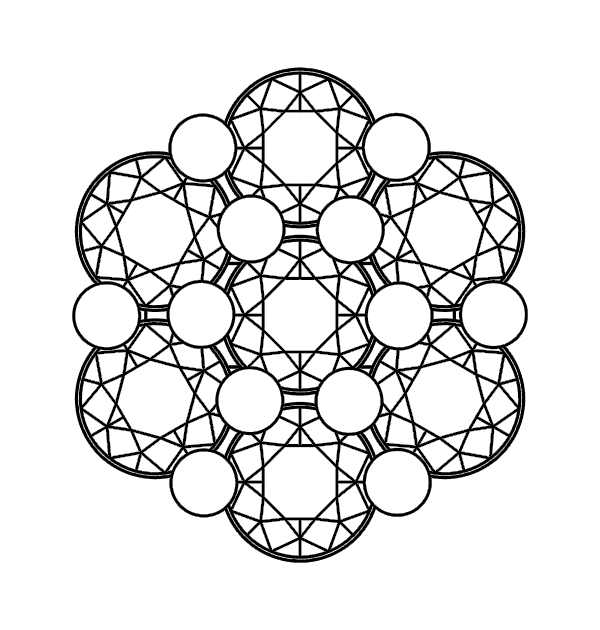

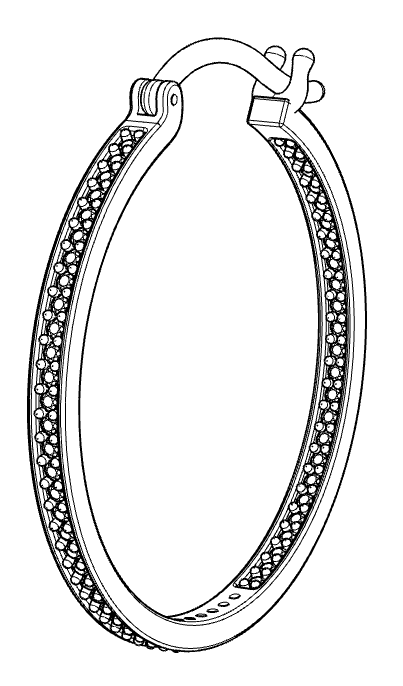

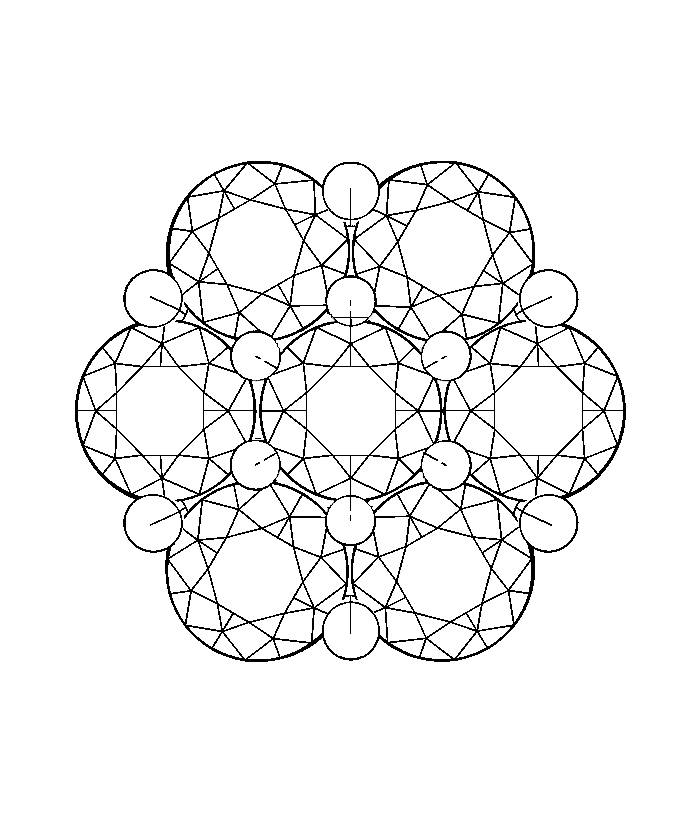

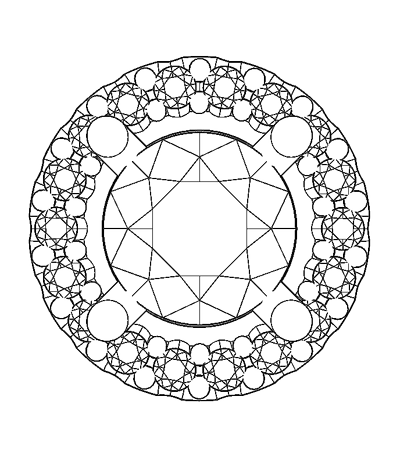

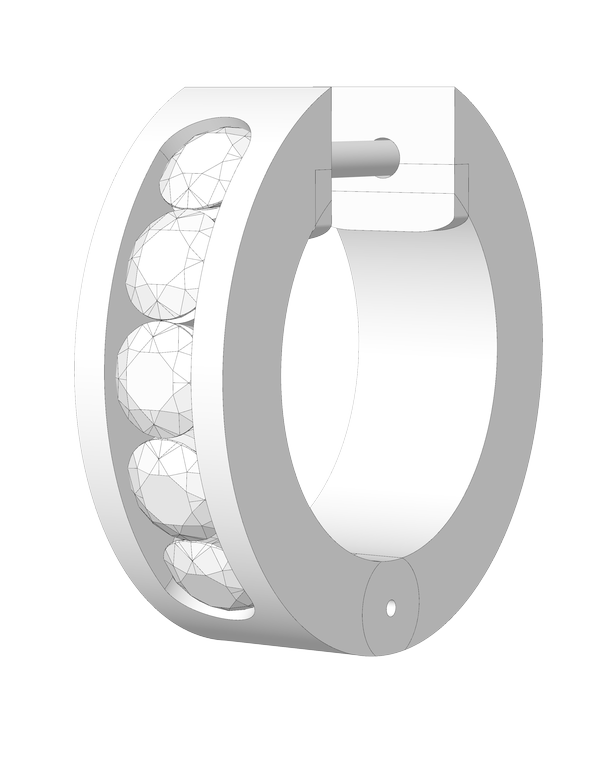

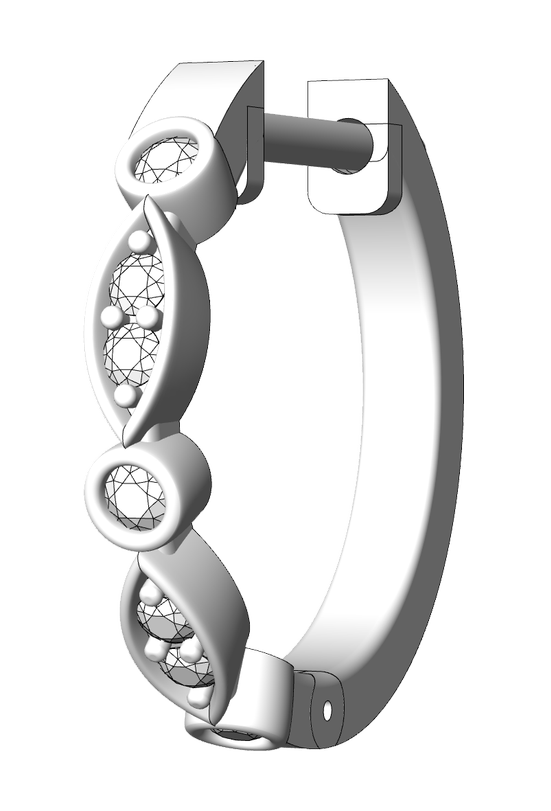

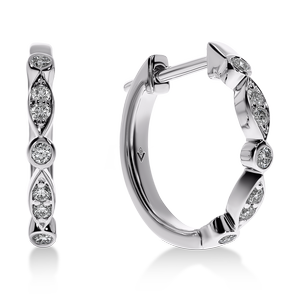

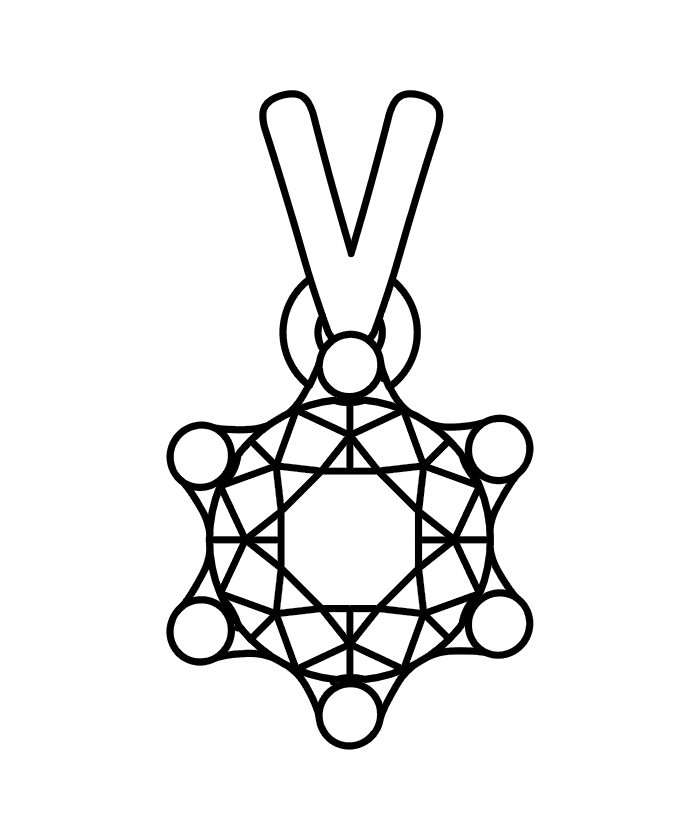

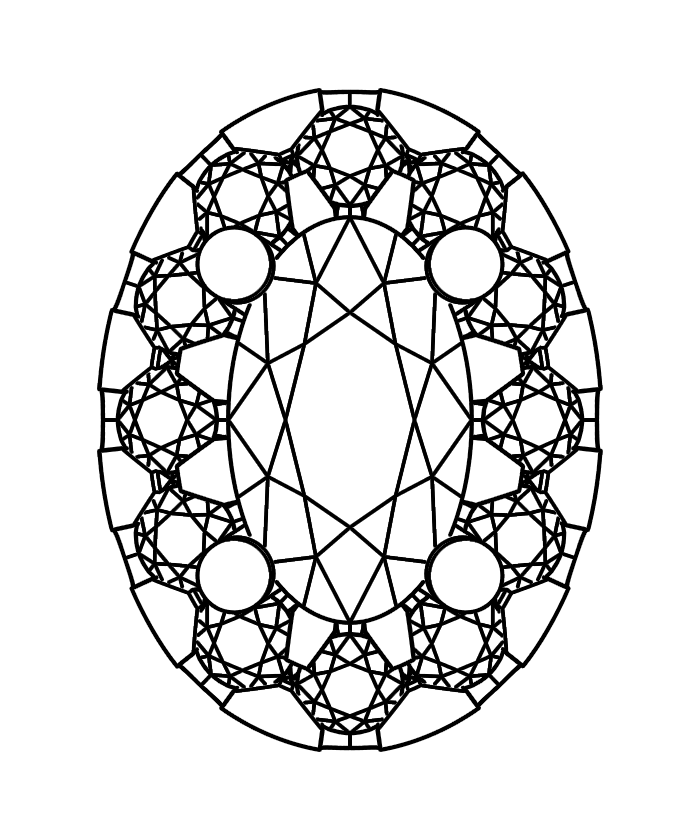

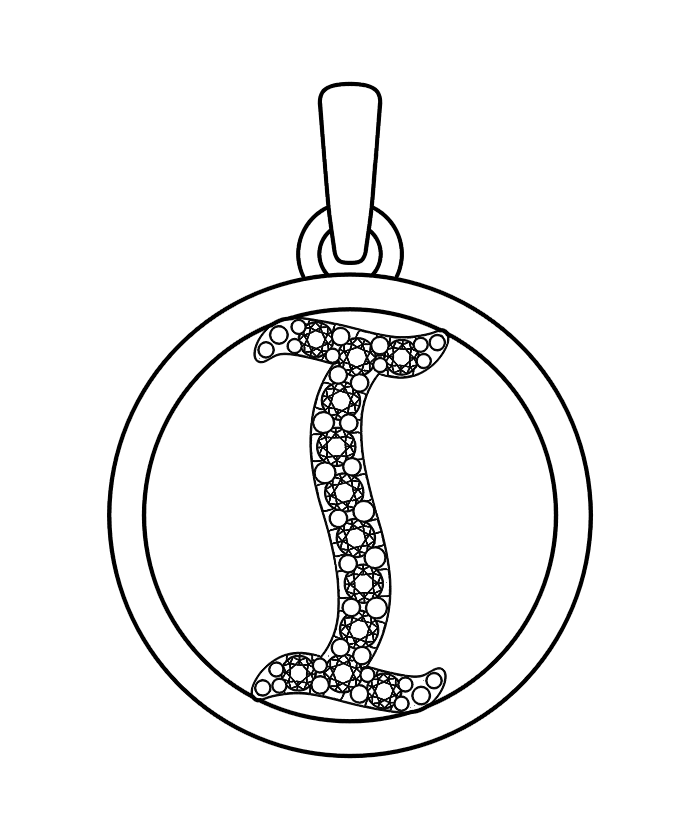

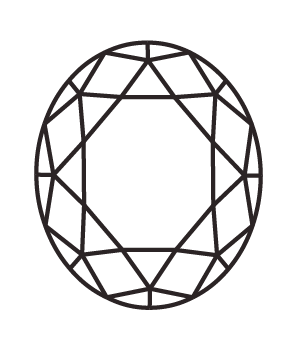

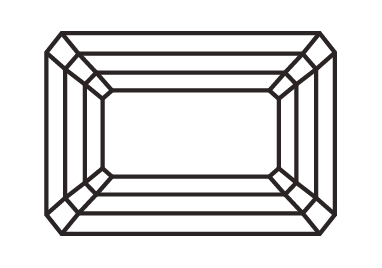

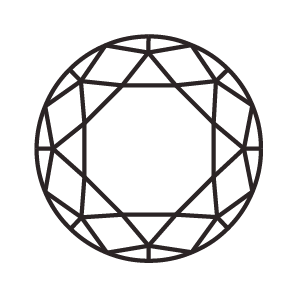

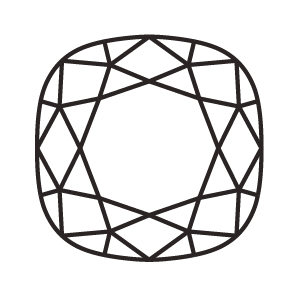

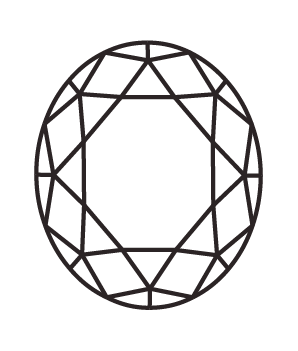

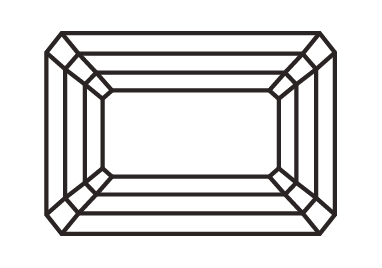

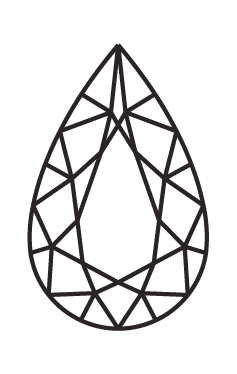

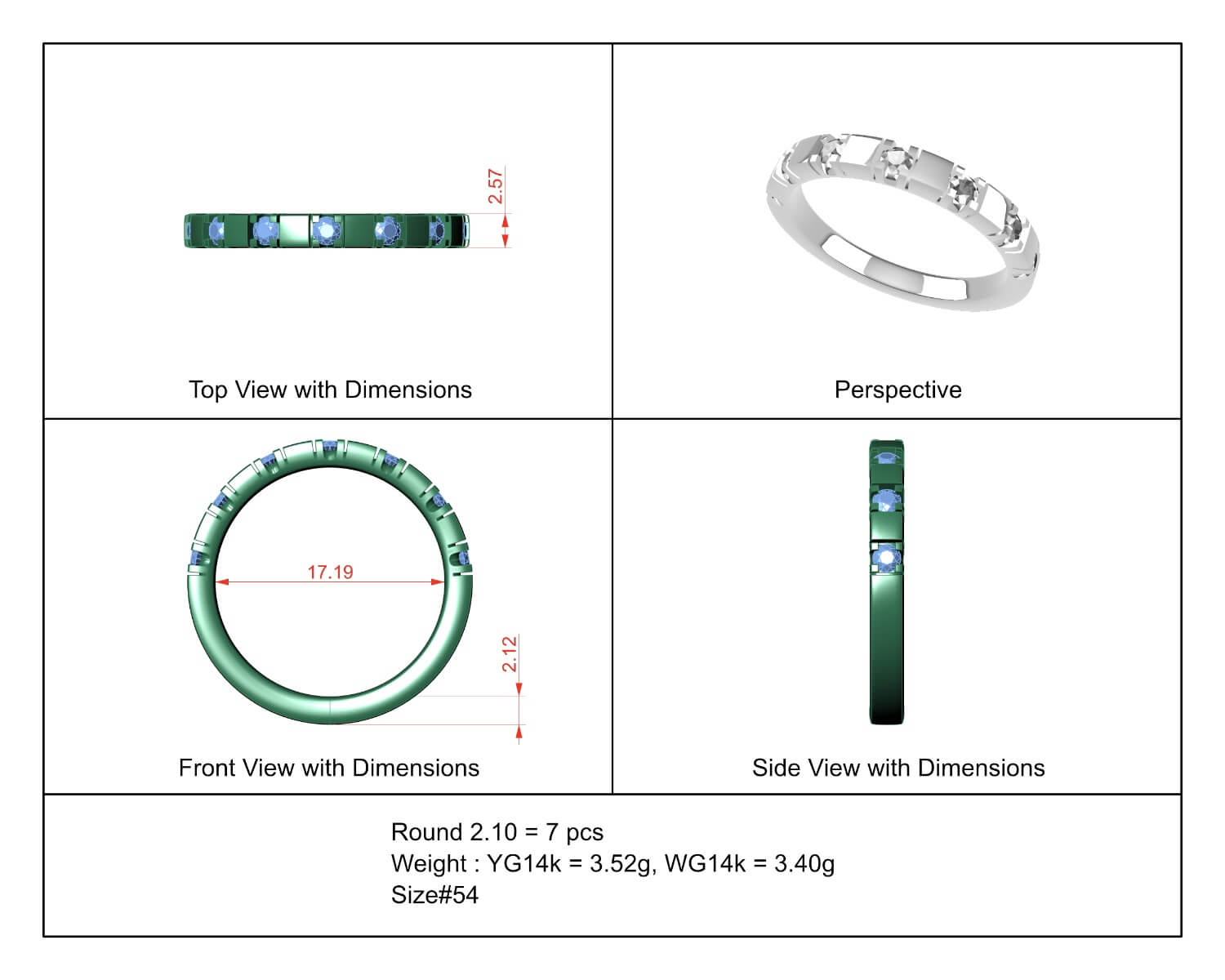

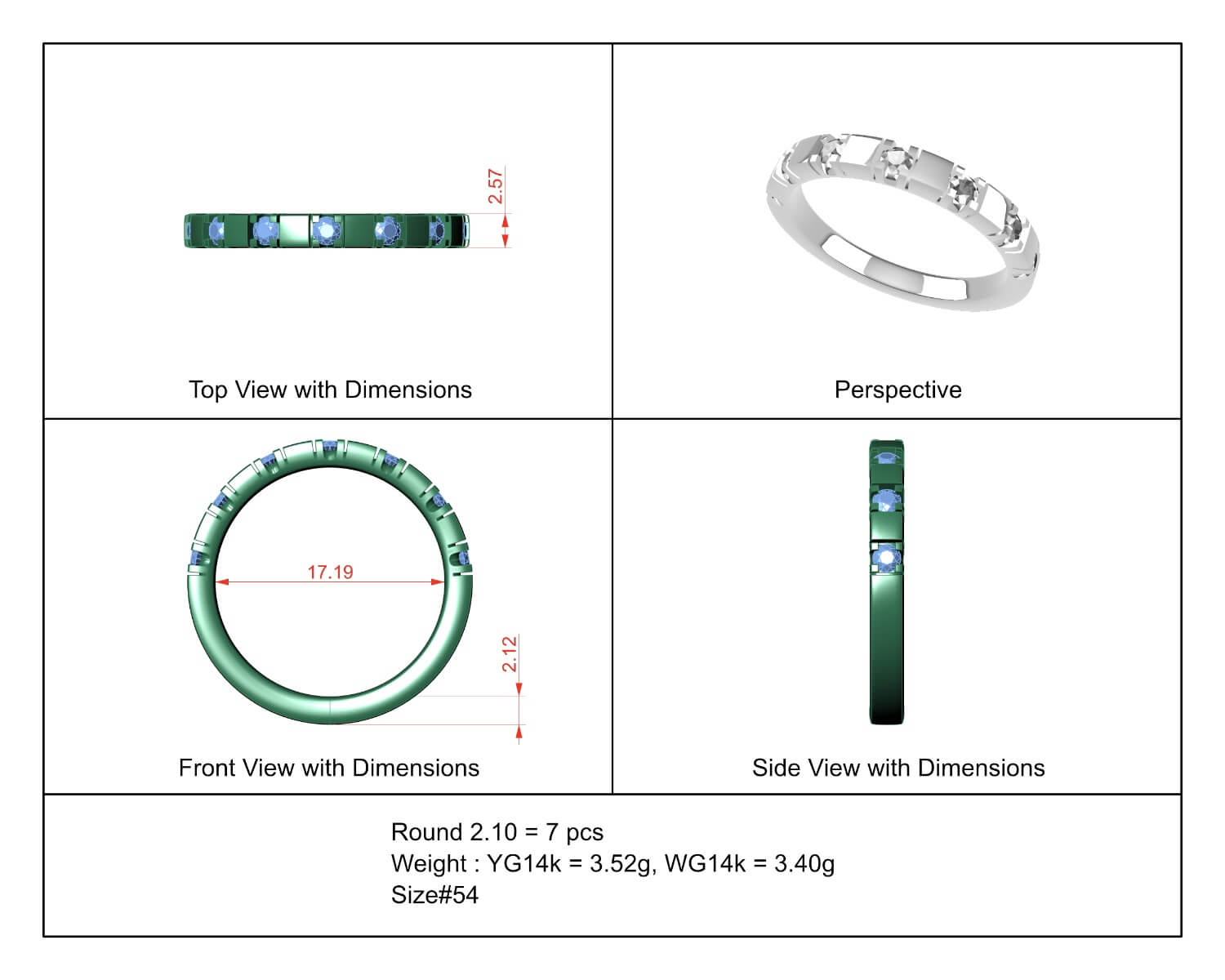

As you can see, these rings created using CAD software are standard in design. So, it is economical to produce them using such technology.

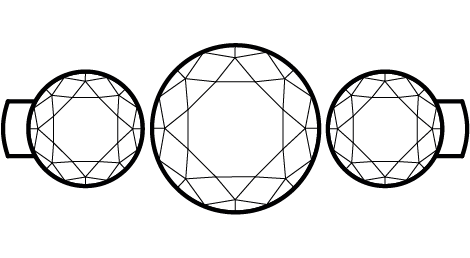

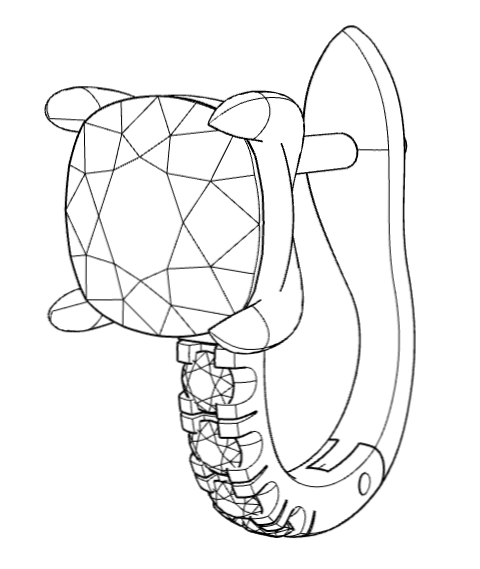

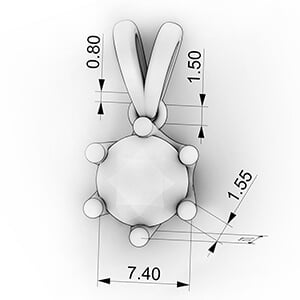

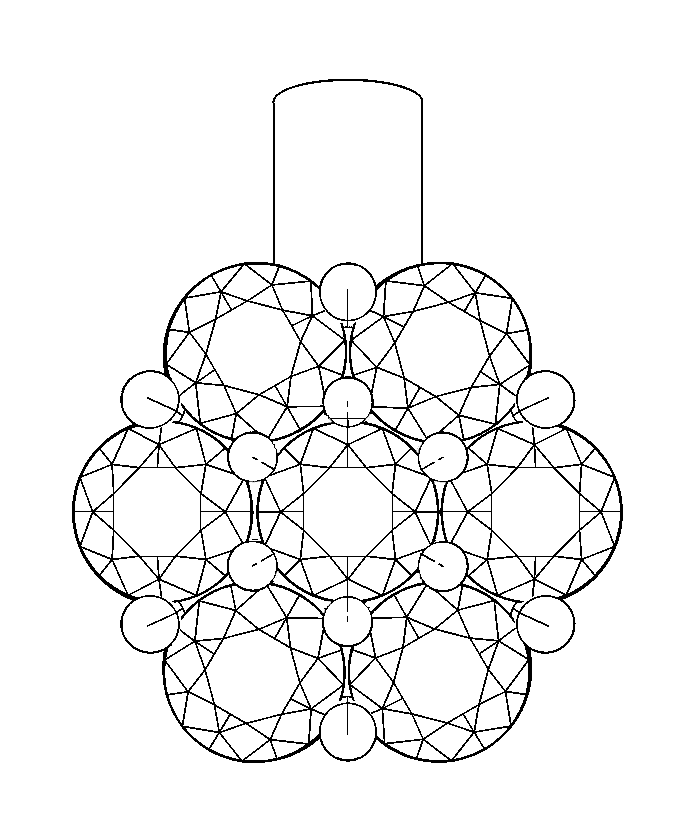

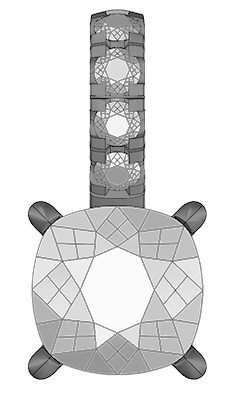

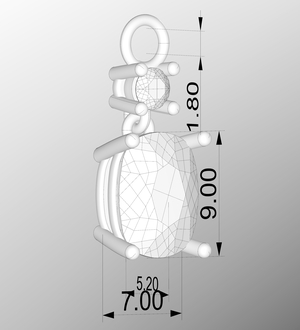

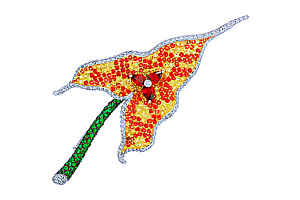

Frog necklace using hand skills and CAD software

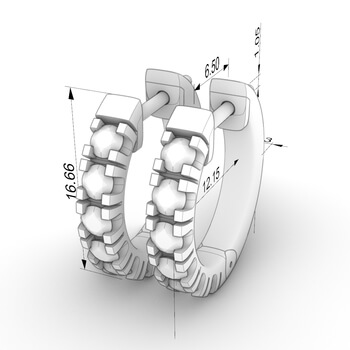

The pendant design in question is a complex piece of jewelry, with many intricate parts that require careful attention to detail. While it is possible to create the design using CAD software, certain aspects of the design would require a significant amount of time to execute, and even then, some final touches would need to be worked out by hand. Therefore, a combination of CAD software and handcrafting would be the optimal approach to producing this pendant. CAD software can be used to create a digital model of the pendant, which can then be used to produce a mold. The mold can then be used to create the basic shape of the pendant. However, certain details, such as the leaf web and volume work and any additional embellishments, would need to be added by hand.

This approach would be both faster and more cost-effective than relying solely on manual labor. By using CAD software to create the basic shape of the pendant, we can ensure that each piece is consistent in size and shape. Additionally, by using handcrafting techniques to add the finishing touches, we can ensure that each piece is unique and has a personal touch. Furthermore, the inclusion of a "handmade" touch to any item, from cars to shoes, bags, or jewelry, always adds value and a distinctive touch. It is this unique combination of technology and craftsmanship that sets this pendant apart, making it a truly exceptional piece of jewelry that is sure to be cherished by its owner for years to come.

Deutsch

Deutsch